- Home

- About Us

- Geothermal

- Grundfos Geothermal Pumps

- Geothermal FLOW CENTERS

- Wilo Geothermal Pumps

- Thermally Enhanced Grout

- HDPE Pipe AND COILS

- HDPE EARTH LOOPS

- PVC Insulated Headers

- Fittings

- HDPE Socket Fusion Tools

- HDPE Socket Fusion Headers

- Plastic Solenoid Valves

- Hose Kits And Accessories

- AutoFill and Backflow Preventer

- Balancing Valves

- Zone Valves

- Glycol Make-up Systems

- Flush And Purge Dolly

- Geo-Loop Leak Seal and Conditioner

- Flow Meters

- Gauges And Thermometers

- Geothermal Expansion Tanks

- Fire Protection

- Fire Pump Manufacturers

- Packaged Fire Pumping Systems

- Fire Pump Accessories

- ETL Certification

- Fire Water Storage Tanks

- Fire Pump Control Panels

- Repair Parts

- Replacement Equipment

- Design

- Service Department

- News

- Contact Us

- Buy Online

- Grundfos Geothermal Pumps

- Geothermal FLOW CENTERS

- Wilo Geothermal Pumps

- Thermally Enhanced Grout

- HDPE Pipe AND COILS

- HDPE EARTH LOOPS

- PVC Insulated Headers

- Fittings

- HDPE Socket Fusion Tools

- HDPE Socket Fusion Headers

- Plastic Solenoid Valves

- Hose Kits And Accessories

- AutoFill and Backflow Preventer

- Balancing Valves

- Zone Valves

- Glycol Make-up Systems

- Flush And Purge Dolly

- Geo-Loop Leak Seal and Conditioner

- Flow Meters

- Gauges And Thermometers

- Geothermal Expansion Tanks

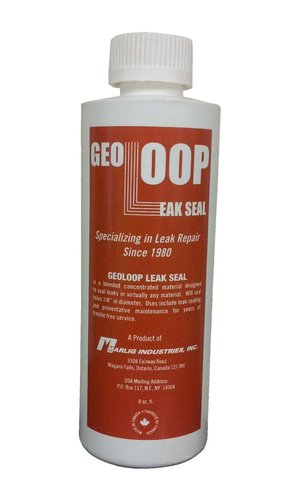

Geo-Loop Leak Seal and Conditioner

Geo-Loop Leak Seal and Conditioner is a great additive for your geothermal closed loop system to help prevent corrosion and leaks in your system. Geo-Loop Leak Seal and Conditioner will coat any surface that it comes in contact with to help maintain the integrity of your geothermal system. Not only will it seal the leaks it comes in contact with but it will also help prevent rust buildup on your pumps and corrosion of other metallic components in your system.

Geo-Loop Leak Seal and Conditioner is a great additive for your geothermal closed loop system to help prevent corrosion and leaks in your system. Geo-Loop Leak Seal and Conditioner will coat any surface that it comes in contact with to help maintain the integrity of your geothermal system. Not only will it seal the leaks it comes in contact with but it will also help prevent rust buildup on your pumps and corrosion of other metallic components in your system.

Geo-Loop Leak Seal can be added via flush cart or through a P&T port in the system.

For minor leaks an 8 oz. bottle will cover systems up to 5 ton. For larger leaks a second bottle can be added.

Geo-Loop Leak Seal and Conditioner is just another way to make sure your system is protected and running at peak performance.

For more information concerning Geo-Loop Leak Seal and Conditioner and a distributor near you feel free to call us at 866-522-0396.

Geo-Loop Leak Seal and Conditioner Instructions

Follow Mixing Directions for Minor Leaks

Shake contents of GEOLOOP LEAK SEAL bottle well before adding

Use an empty container that is two or three times the size of the intended amount of GEOLOOP LEAK SEAL to be added

Fill the empty container nearly half full of water and then pour in the GEOLOOP LEAK SEAL and shake or stir until well mixed

This product is nearly always compatible with glycol or antifreeze mixtures. If possible, premix a small amount of glycol or antifreeze, from the loop, into the container

If the solution turns into a buttermilk consistency, it would be advisable to purge the system and run the GEOLOOP LEAK SEAL through the loop with water, until you feel the leak has been sealed

Allow 48 hours before pressure testing up to the desired psi

If pressure holds, remove the water from the loop and replace with original solution

DIRECTIONS FOR USE:

Prescribed amounts:

Add 8 ounces of GEOLOOP LEAK SEAL for each 5 tons of ground loop

Add 16 ounces of GEOLOOP LEAK SEAL for 6 – 10 tons of ground loop and increments of 8 ounces for every additional 5 tons of ground loop

Incorporate GEOLOOP LEAK SEAL into loop field by one of the following methods:

For preventative maintenance of vertical or horizontal ground loops, mix one 8 ounce bottle of GEOLOOP LEAK SEAL and add to the geothermal loop field while purging the system or by introducing it through the p/t provided the system is up and running and that re-flushing is not necessary

For troublesome loops, where water loss may be evident because of equipment age, poor connections, fusion joints, old PVC glue joints, or any other condition causing a system to lose fluid, first repair all of the obvious areas that can be found then add the prescribed amounts, as previously mentioned, to the ground loop as described above.

If the fluid loss is expected to be underground and there is the possibility of a bad fusion, add double the amount. Keep the loop pressured-up and give the GEOLOOP LEAK SEAL sufficient time to repair itself.

Notes:

GEOLOOP LEAK SEAL is not ideal to use if pressure gauges, containing air spaces, are installed “in line” because the product could coat the gauge and possibly give an inaccurate reading

GEOLOOP LEAK SEAL helps coat all internal parts of the water passageway and slows scaling and deterioration of cast iron pumps which is a benefit. Scaling and deterioration causes pitting and pinholes, thus causing water to show a red color (rust) which may result in future problems.

GEOLOOP LEAK SEAL is effective for almost any material and is also very effective at sealing improper or cross threaded pipe fittings.

Most installations do not run into leak problems, but if you do, GEOLOOP LEAK SEAL should solve many of the leak problems you may encounter in a geothermal installation.